About BDP®

How It Works

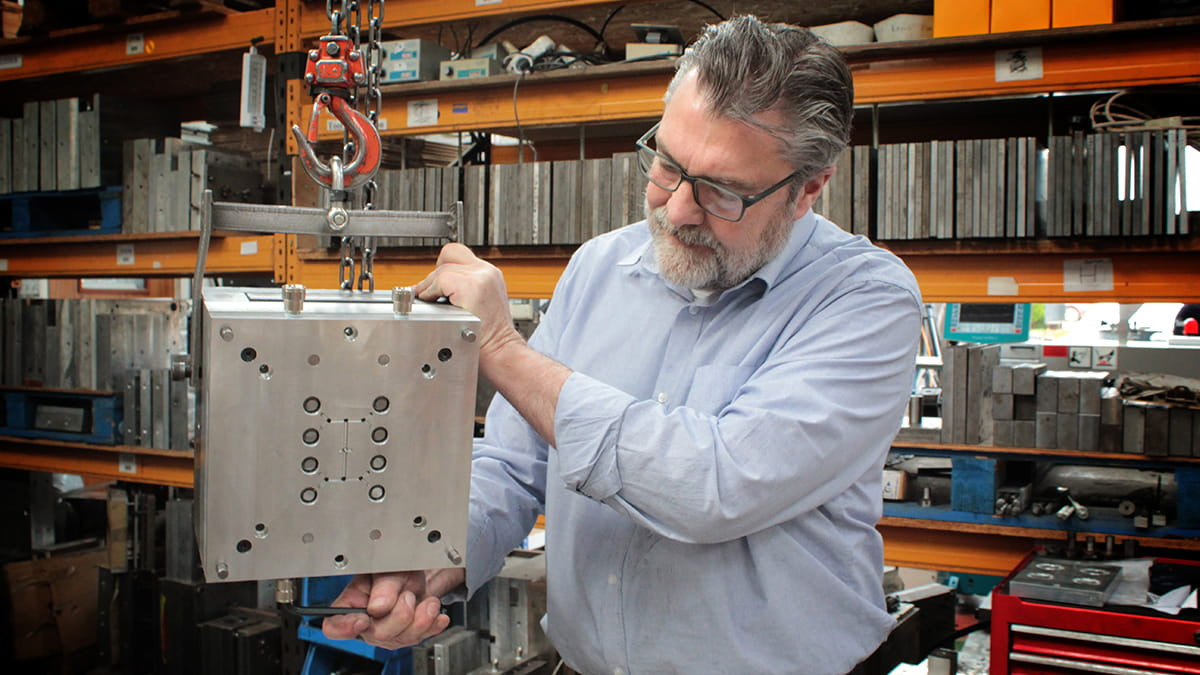

The process operates by incorporating organic nutrients and compounds, which serve as microbial food sources found in nature, into plastic. This addition effectively deceives microbes, enticing them to consume the plastic as if it were their natural sustenance. Following the plastic's usage, recycling, and disposal, these minute bacteria devour it entirely, resulting in the production of compost and biogas. The compost enriches the soil, while the captured biogas can be transformed into natural gas. This entire cycle illustrates the functionality of injection moulding in utilising BDP® technology.

A Little More Technical

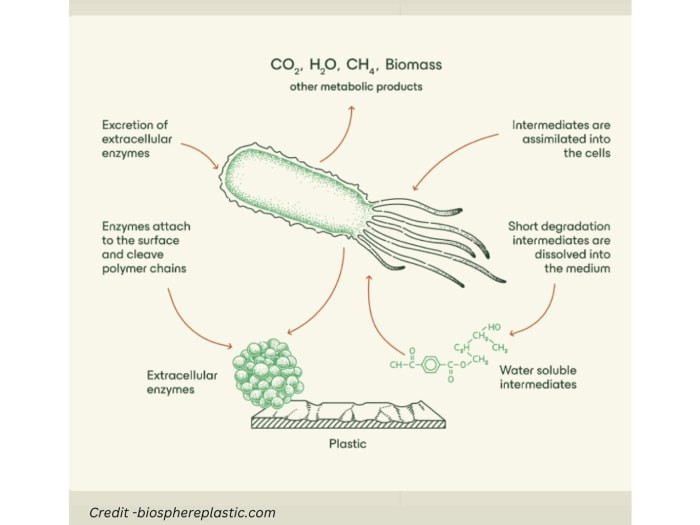

In the realm of micro-organisms, BDP® serves as a magnet for microbes, enticing them to colonise the surface of the plastic. Through the secretion of enzymes by these microbes, the plastic undergoes a transformation, becoming hydrophilic, or water-attracting. Consequently, a biofilm, teeming with microbes and moisture, develops and firmly attaches to the plastic's surface. Subsequently, the microbes proceed to break down the plastic through hydrolysis, facilitated by the enzymes and water. As the polymer chains disintegrate into individual monomers, the microbes feast upon the polymer matrix. Throughout this degradation process, the microbes emit signals, drawing in more of their kind to partake in consuming the plastic mass. Ultimately, the majority of the CO2 and other by products formed in earlier stages are consumed, leaving behind predominantly methane, which can be captured for the production of clean energy. This intricate process exemplifies the role of injection moulders in harnessing BDP® technology.

BDP® AT A GLANCE

- BUDGET-FRIENDLY

- AVAILABLE IN ANY COLOUR

- BIODEGRADABLE IN LANDFILL

APPLICATION

BDP® can be applied to almost any virgin material, transforming it into a biodegradable product. This not only means you have a high amount of flexibility in product application, but you also have food-grade approval. Due to the low dosage of additive required, BDP® is also a very budget-friendly option for injection moulding.

TECHNICAL DATA SHEET AVAILABLE UPON REQUEST

Process

Hydrolysis marks the initial phase in the biodegradation process, involving the introduction of water to disassemble the covalent bonds linking the monomers forming polymers. In contrast, condensation eliminates water to facilitate the bonding of monomers. Condensation reactions, being energy-absorbing processes for monomer-to-polymer linkage, store energy, whereas hydrolysis releases it. These reactions typically follow this pattern: R1 – R2 + H2O ←→ R1 – O + R2 – H+

Moving on to acidogenesis, it signifies the subsequent step in anaerobic digestion. During this phase, fermentative bacteria cultivate an acidic environment while generating ammonia, H2, CO2, H2S, shorter volatile fatty acids, carbonic acids, alcohols, and trace quantities of other byproducts. While acidogenic bacteria break down organic matter, the resulting biomass remains too substantial and impractical for the ultimate aim of methane production.

Acetogenesis, on the other hand, involves the production of acetate, a derivative of acetic acid derived from the carbon and energy sources generated by acetogens. These microorganisms metabolize many of the products originating in acidogenesis into acetic acid, CO2, and H2. Acetogens facilitate the decomposition of biomass to a level where methanogens can take over.

Methanogenesis represents the final stage in anaerobic digestion, where methanogens utilize acetic acid and carbon dioxide—the primary byproducts of the first three steps in anaerobic biodegradation—to synthesize methane. This reaction may take the form of CO2 + 4 H2 → CH4 + 2H2O or CH3COOH → CH4 + CO2. However, the primary pathway for methane generation primarily involves acetic acid.