Product Design

At Great Central Plastics, we recognise that a well-designed product sets the stage for success. Our team of product designers and engineers collaborates closely with our clients to transform their ideas into tangible, market-ready products. Using the latest Computer-Aided Design (CAD) software and advanced modelling techniques, we create precise 3D designs that optimise functionality, manufacturability, and aesthetics. Our design process places a strong emphasis on Design for Manufacturability (DFM) principles, ensuring seamless integration with our state-of-the-art injection moulding processes.

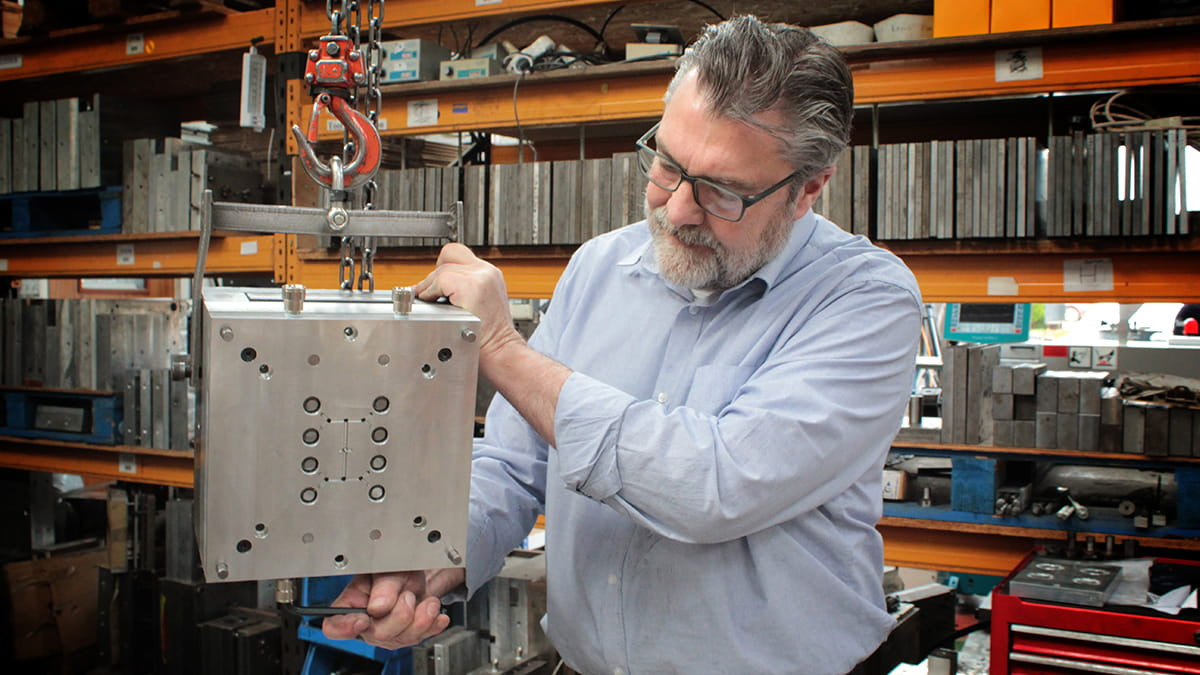

Injection Moulding Facilities

Equipped with cutting-edge injection moulding facilities, we possess the capability to produce components of varying complexities and sizes. Our advanced machinery, combined with an extensive range of materials, enables us to cater to the diverse needs of various industries. Whether you require simple or intricate parts, high-volume production or low-volume runs, we offer the flexibility to accommodate your specific requirements. Our experienced technicians ensure high levels of precision, efficiency, and consistency throughout the entire manufacturing process.

Designing for Plastic Injection Moulding - Key Considerations

When designing a product for plastic injection moulding, certain factors play a crucial role in ensuring optimal outcomes. Here are some important considerations:

Design for Manufacturability: Incorporate manufacturability into the part design phase, understanding the capabilities and limitations of the injection moulding process. Design parts with features that can be easily moulded, assembled, and released from the mould.

Wall Thickness: Maintain consistent and uniform wall thickness throughout the part design to avoid issues such as uneven cooling, sink marks, warping, and difficulty in mould filling. Aim for thin and uniform wall thickness while ensuring structural integrity.

Draft Angles: Include draft angles in the design to facilitate easy part ejection from the mould. Draft angles minimise friction, reduce the risk of part damage, and help maintain dimensional accuracy.

Ribs and Bosses: Utilise ribs and bosses to enhance part strength and stiffness without significantly increasing material volume. Proper placement and design of ribs and bosses ensure part integrity while minimising material usage.

Fillets and Corner Radii: Incorporate fillets and corner radii to eliminate sharp edges and stress concentration points, improving part aesthetics and reducing the risk of stress fractures.

Gate and Runner Placement: Strategically position gates and runners to ensure uniform material flow and minimise cosmetic defects. Proper placement helps achieve optimal filling and consistent part quality.

Undercuts and Side-Actions: Minimise the use of undercuts or complex side-actions to reduce tooling complexity and cost. If necessary, consider incorporating mechanical or hydraulic side-actions to enable easy ejection from the mould.

Parting Lines and Part Symmetry: Define parting lines that ensure symmetry and balanced filling, preventing issues like uneven shrinkage and warping.

Material Selection: Choose the appropriate plastic material based on the application's requirements, considering factors such as shrinkage rates, mechanical strength, temperature resistance, and chemical compatibility.

Tolerances and Dimensional Accuracy: Clearly define desired tolerances and dimensional specifications, accounting for the capabilities of the injection moulding process.

Rest assured, our expert team will guide you through these considerations and offer suggestions to enhance functionality, reduce costs, and increase sustainability. Reach out to us today to discuss your project requirements and embark on a successful product design journey.

Please get in touch to discuss your project's requirements.