Company History

The History of Great Central Plastics: Crafting Excellence Since 1998

At Great Central Plastics, our story began in 1998. From our base in Northamptonshire, UK, we’ve steadily grown to become one of the leading injection moulding companies in the region. Our expertise lies in precision-crafted plastic components, tailored specifically to the automotive industry. Whether it’s automotive badges or other critical parts, we deliver reliable, high-quality solutions that meet the industry’s exacting standards.

Where It All Began

Our journey began in 1998 after a realisation that if you want to be in full control of the service you offer, you need to do it yourself: a commitment to delivering excellence in injection moulding.

Tony was in sales for another injection moulder, and frustration with missed delivery dates due to production constraints led to him seeking a solution. With a passion for quality and reliability, Tony explored options to set up his own company.

Two Machines, One Vision

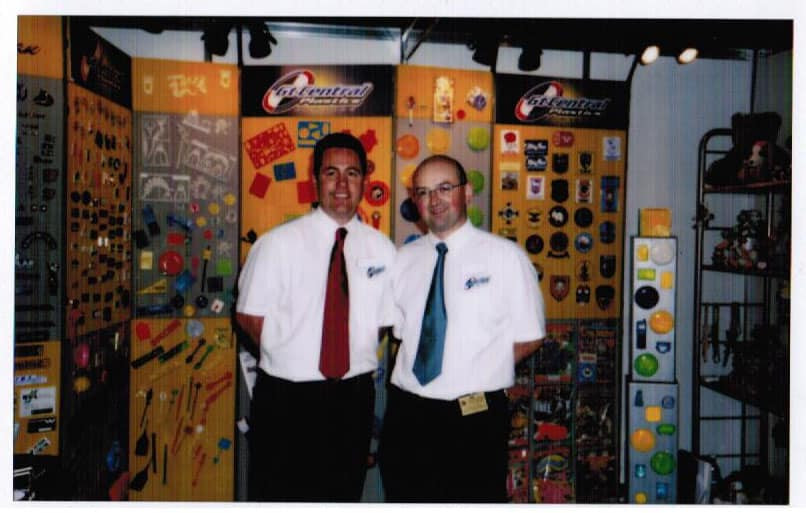

Joined by Darryl, a skilled tool maker, the two of them forged a partnership in which projects could be tooled and moulded reliably under one roof.

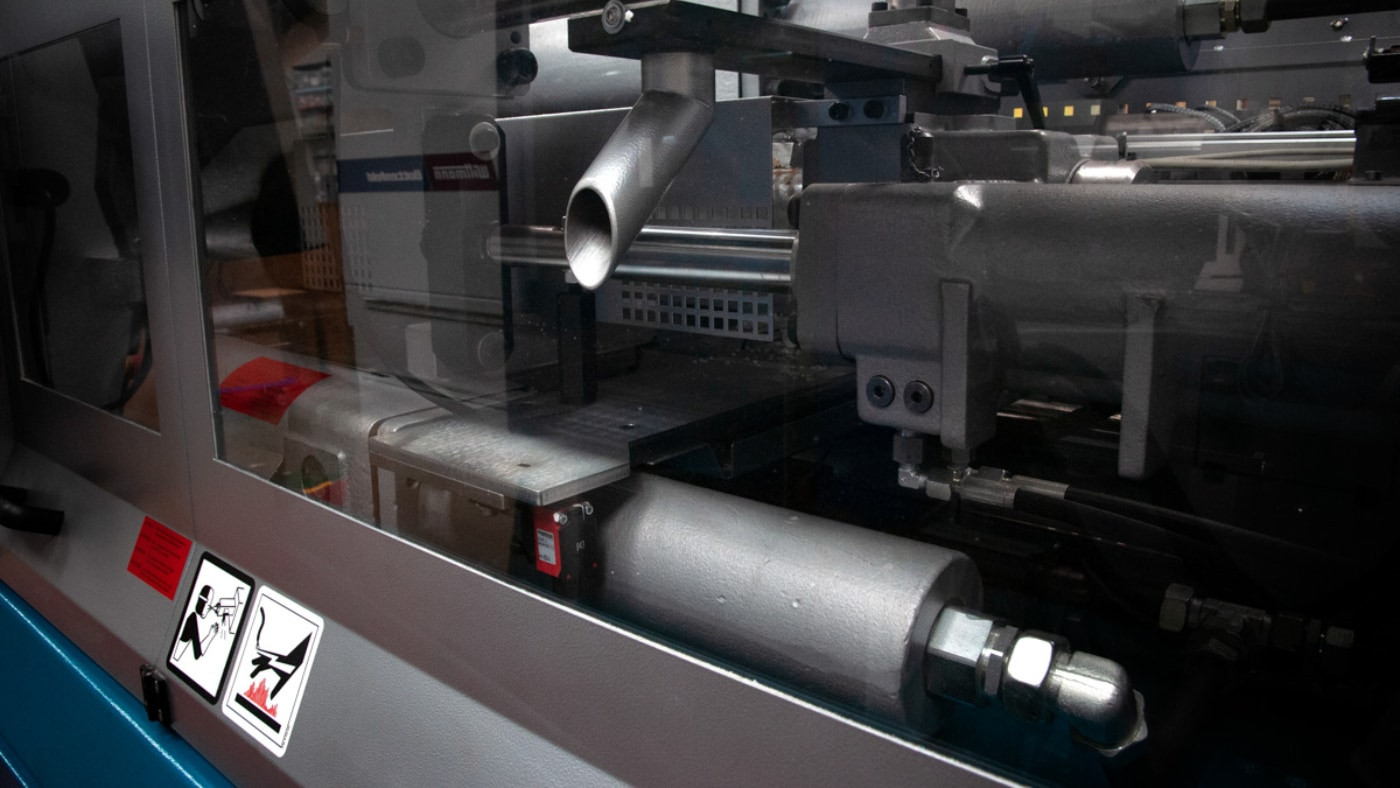

Injection moulding with just two machines, the Great Central Plastics venture started, investing our own resources into ensuring every product met our high standards of injection moulding.

Partnerships in Precision

Our inaugural projects, from crafting Red Crosses for The Jesus Army to supplying McDonald's with party essentials, laid the foundation for this new injection moulder.

With each milestone, our reputation for excellence blossomed, attracting renowned clients like Honda and JLR, forging lasting relationships with industry leaders in automotive badges.

Accredited Growth

From humble beginnings in 1998, operating out of two modest units, to our landmark move to our current facility in 2001, ownership of our premises marked a significant triumph.

Achieving ISO9001 accreditation further solidified our commitment to quality in injection moulding, opening doors to prestigious partnerships and major accounts.

From Aperol to Cadbury

The business continued to grow in a number of industries including the food and drinks sector where we manufacturing POS for the likes of Smirnoff, Aperol, Cadbury’s and Petit Filous.

Eco-friendly Moulding Moves

In 2011, we took another bold step towards sustainable manufacturing by integrating solar panels into our operations, contributing to 30% of our energy needs.

This commitment to eco-friendly practices reflects our dedication to both quality and the environment in injection moulding.

New Era, Sustainable Future

In March 2021, Tony and Darryl retired, passing the torch to the next generation. With Bal Phillips at the helm as Managing Director, the new leadership team is poised to lead Great Central Plastics into a new era of sustainable manufacturing.

Our focus remains on innovation and sustainability, developing new solutions for products and forging partnerships with clients in emerging industries, all while maintaining our excellence in injection moulding and automotive badge solutions.

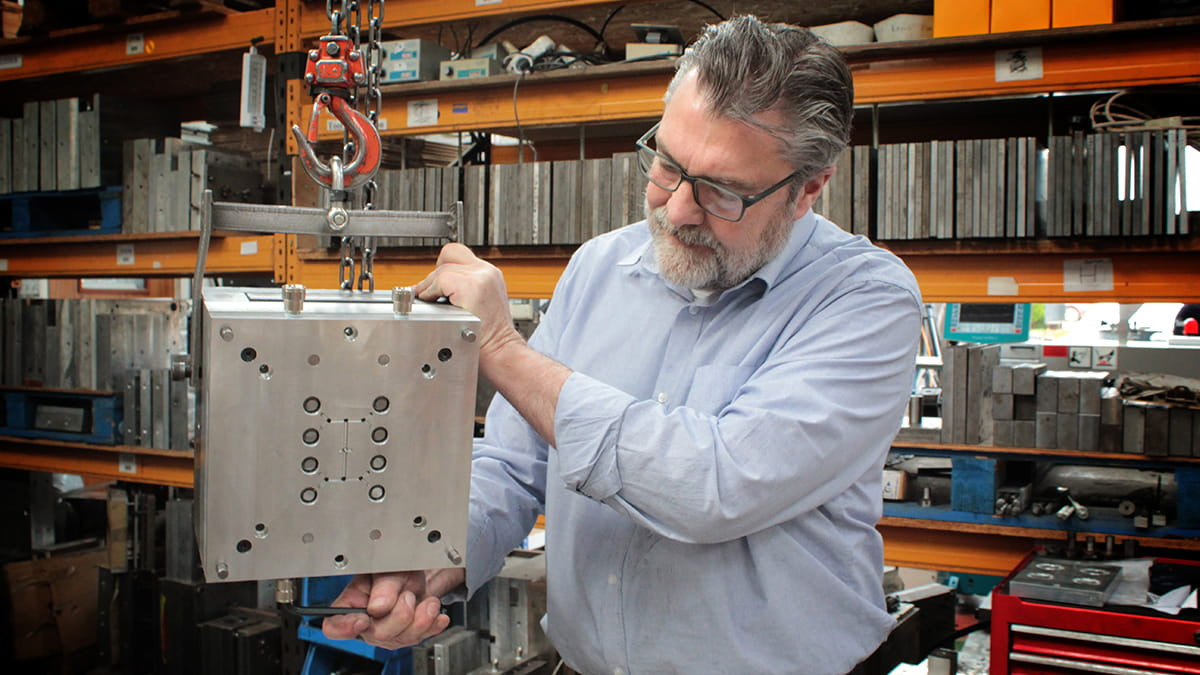

16 Experts, 13 Machines

Great Central Plastics now employs 16 members of staff and houses 13 moulding machines within our 10,500 sq ft site.

Alongside our in-house tool room and post-production assembly area we are able to cater to your project requirements right here in the UK.

Happy customers

Get a Quote